If you're an electrical engineer or sourcing manager working in industries like medical devices, aerospace, or industrial automation, chances are you've come across the terms PCB and PCBA. At a glance, they may seem interchangeable, but in the world of electronics manufacturing, they mean very different things. Understanding the distinction is critical, especially when sourcing, designing, or assembling complex electronic systems.

At EI Sales, we provide solutions at every stage of the electronic manufacturing journey. From bare printed wiring boards (PWBs) to full turnkey PCBA builds, our vertically integrated capabilities help OEMs move seamlessly from concept to production.

Here’s a breakdown of PCB vs PCBA, and why it matters.

What is a PCB?

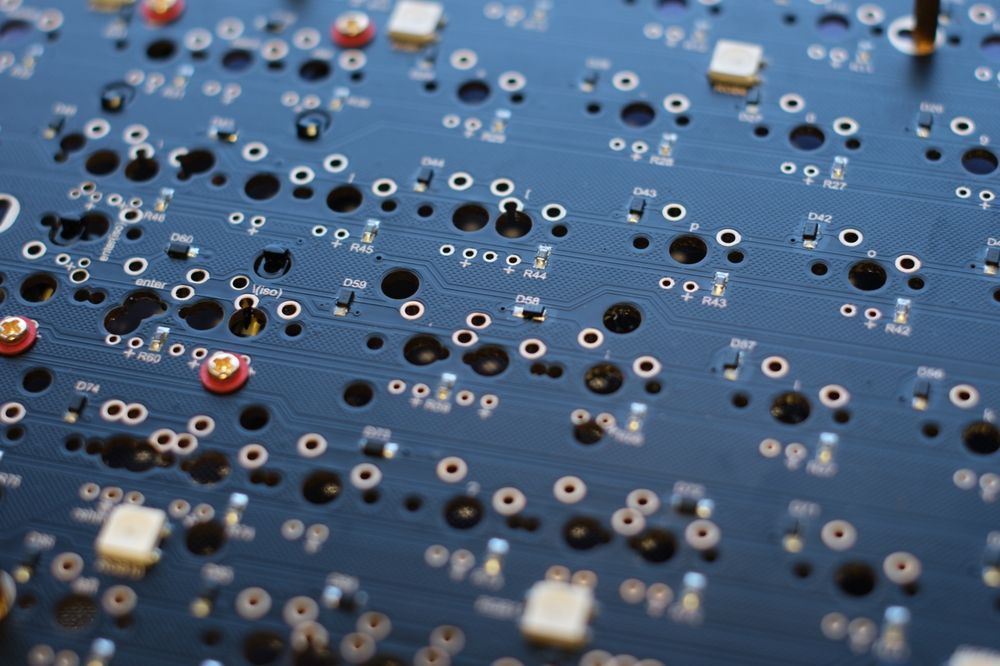

PCB stands for Printed Circuit Board. A PCB is the bare, unpopulated board that serves as the foundational structure for most electronic devices. It is made from a non-conductive substrate, typically FR-4 fiberglass, laminated with conductive copper traces that form the circuit layout.

There are several types of PCBs depending on complexity and application:

- Single-layer PCB: Copper traces on one side only. Simple and cost-effective.

- Double-layer PCB: Copper traces on both sides. Offers more routing flexibility.

- Multilayer PCB: Multiple layers of copper separated by insulating material. Ideal for complex circuits like those found in medical imaging or avionics systems.

Bare PCBs are manufactured to precise electrical and mechanical tolerances. This includes features like via structures (through-hole, blind, buried), solder mask, and silkscreen. At EI Sales, we provide bare PWB solutions ranging from 4 to 24 layers, built to IPC-6012 Class 3 and MIL-PRF-31032 standards, ensuring reliability for mission-critical applications.

However, a PCB on its own is inert. It won’t do anything until electronic components are added.

At EI Sales, we support customers with both prototype and production PCB production. We represent Multicircuits for rigid PCB quick-turn prototypes and volume production. US production from 2 to 28 layers with certifications that allow them to build for military, aerospace, space, medical and industrial applications.

What is a PCBA?

PCBA stands for Printed Circuit Board Assembly. This is the next stage in the production lifecycle. A PCBA refers to a PCB that has components soldered to it, in other words, it’s a working circuit board ready to be integrated into a system.

A typical PCBA may include:

- Semiconductors (e.g., MOSFETs, JFETs, rectifiers)

- Capacitors, resistors, and inductors

- Connectors and switches

- Microcontrollers and memory ICs

- LEDs and displays

- Wire harness interfaces

At EI Sales, we support customers with both prototype and production PCBA services, offering turnaround as fast as 24 hours. Whether it’s a one-off test board for a new medical sensor or a multi-board production run for an industrial automation client, we provide full traceability, inspection, and 100 percent functional testing to meet the highest quality standards.

Key Differences Between PCB and PCBA

| Feature | PCB | PCBA |

|---|---|---|

| Definition | Bare circuit board | Circuit board with components assembled |

| Function | Passive structure | Active and functional unit |

| Stage | Early stage of manufacturing | Later stage, post-assembly |

| Complexity | Varies by layer count and features | Depends on part count and assembly requirements |

| Services Involved | Fabrication only | SMT, through-hole, testing, inspection |

| Value to OEM | Foundation for circuit design | Ready-to-integrate subassembly |

Why the Difference Matters

For OEMs and engineers, knowing whether you're sourcing a PCB or a PCBA changes everything, from lead time and logistics to testing and compliance. Here’s why this distinction is crucial:

- Lead Time Planning: Bare PCBs can be fabricated in 5 to 15 days depending on complexity, but a PCBA build requires sourcing components and often includes test development.

- Cost Structure: PCB costs are largely based on layer count, materials, and board size. PCBA costs include not just the board, but all components, placement, soldering, and quality assurance.

- Testing Requirements: PCBs undergo electrical tests for shorts and opens. PCBAs are functionally tested to ensure performance. Basic testing starts with a flying probe and progresses to bed-of-nails, and full functional test development. EI Sales can help you with everything from basic flying probe to full functional test development.

- Compliance and Certifications: A PCB might be IPC-6012 certified, but a PCBA intended for medical or aerospace use may require ISO 13485, AS9100, or ITAR compliance. EI Sales maintains all relevant certifications to support these needs.

Choosing the Right Partner

Selecting a vendor who understands the complete process, from PCB to PCBA, is essential for maintaining quality and meeting deadlines. Many vendors focus on one side or the other, but few offer both design and manufacturing expertise under one roof.

At EI Sales, we go beyond traditional manufacturer’s rep roles by also operating as a quick-turn prototype assembler, electronic contract manufacturer , cable and harness house, and even a OEM of sensors. Our customers don’t have to piece together services from multiple providers. Instead, they get a streamlined ecosystem of solutions designed for speed, quality, and scalability.

From quick-turn prototypes to full-scale production, our solutions-oriented approach gives OEMs the confidence to move forward. Whether you’re launching a new design or scaling up an existing one, EI Sales is your end-to-end partner in electronic manufacturing.