As battery-powered devices become more advanced across medical, aerospace, industrial, and vehicle applications, engineers are frequently asked to specify between lithium-ion (Li-ion) and lithium-polymer (LiPo) battery packs. While both chemistries belong to the lithium family and share many similarities, their performance characteristics and physical formats can differ substantially. Selecting the right chemistry is critical to optimizing reliability, safety, and efficiency in your design.

What They Have in Common

Both lithium-ion and lithium-polymer batteries:

- Are rechargeable

- Offer high energy density compared to older chemistries such as nickel-metal hydride or lead-acid

- Use lithium cobalt oxide (LiCoO₂) or other lithium-based cathode materials

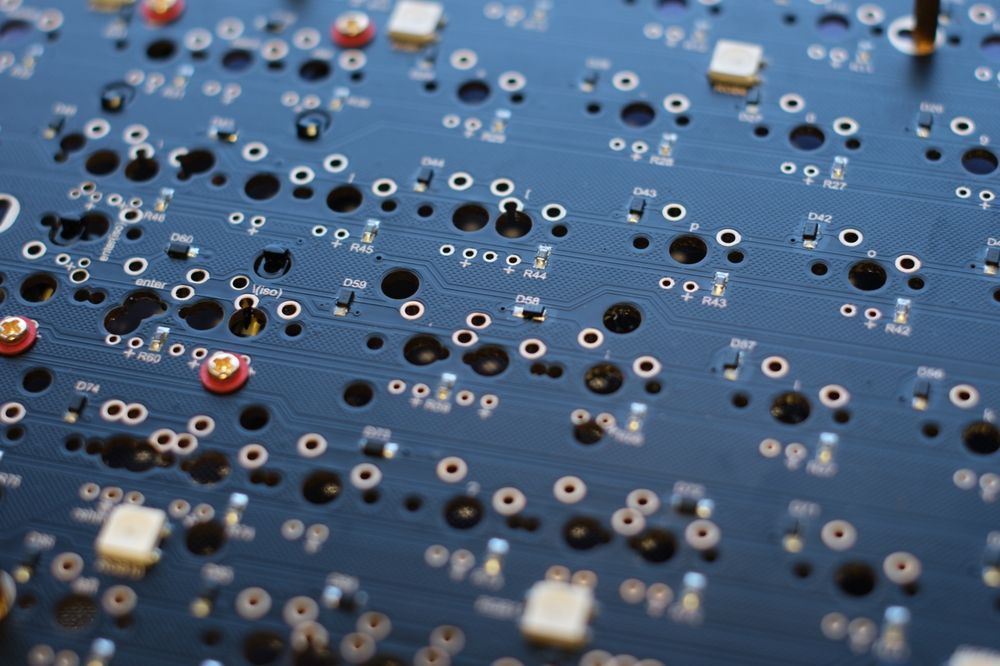

- Require protective circuitry to guard against overcharging, deep discharge, and thermal instability

The differences lie in construction, form factor, and application suitability.

Lithium-Ion: The Workhorse of High-Density Power

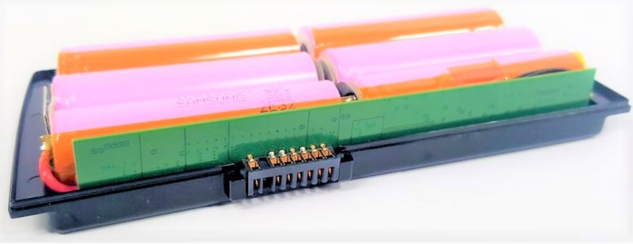

Lithium-ion batteries are built using liquid electrolytes contained within rigid cylindrical or prismatic cells. These packs are favored for their high energy density, consistent cycle life, and relatively low self-discharge rates.

Advantages of Lithium-Ion:

- Higher energy density per unit volume

- Typically longer cycle life under controlled charge/discharge conditions

- Lower manufacturing cost at scale

- Better suited for applications where weight and form factor are less critical

Common use cases include medical carts, portable instrumentation, industrial sensors, and power tools, where energy storage and long run-time are top priorities.

Considerations:

Lithium-ion cells are more susceptible to swelling or leakage if damaged or poorly managed thermally. They require more robust housing and control circuitry to mitigate risk in harsh environments.

Lithium-Polymer: Flexible and Lightweight

Lithium-polymer batteries utilize a solid or gel-like electrolyte encased in a flat, flexible pouch. While the core chemistry is similar to lithium-ion, LiPo packs are known for their adaptability and compact design.

Advantages of Lithium-Polymer:

- Flexible form factors and lower profile design options

- Lightweight construction

- Less prone to leakage due to lack of liquid electrolyte

- Ideal for custom-shaped enclosures or space-constrained designs

These packs are often used in wearable medical devices, aerospace equipment, and robotics, where space optimization and reduced weight are crucial.

Considerations:

Lithium-polymer batteries may offer slightly lower energy density and a shorter cycle life under aggressive usage compared to lithium-ion. They also tend to be more expensive per watt-hour.

Choosing the Right Pack

Ultimately, your application will dictate the ideal chemistry. If your design prioritizes energy density, long battery life, and lower unit cost, lithium-ion may be the better option. For designs where space, shape, and weight matter most, lithium-polymer can provide the flexibility you need.

In both cases, proper design of the battery management system (BMS), thermal controls, and protective circuitry is essential to ensuring long-term reliability and safety.

Need help evaluating the right power solution for your next design? EI Sales provides solutions across a broad spectrum of power technologies and can help connect you with the right supplier and support for your specific application.