When specifying connectors for industrial, medical, or transportation applications, engineers often ask a key question: Should we use M8 or M12 connectors?

Both are compact circular connectors designed for rugged environments, but they are optimized for different functions. Choosing the right connector impacts performance, serviceability, and long-term reliability.

At EI Sales, we support OEMs with more than just products. We provide solutions built around your technical requirements, design constraints, and production timelines. Below, we explain the key differences between M8 and M12 connectors so you can make the right call for your next project.

Understanding the Basics

M8 and M12 connectors are named for the diameter of their threaded locking interfaces: 8 millimeters for M8 and 12 millimeters for M12. Both types are standardized under IEC 61076 and commonly used in environments where signal integrity and ingress protection are critical.

Each offers multiple pin counts and coding options that define what the connector can carry, whether it is power, signal, or high-speed data.

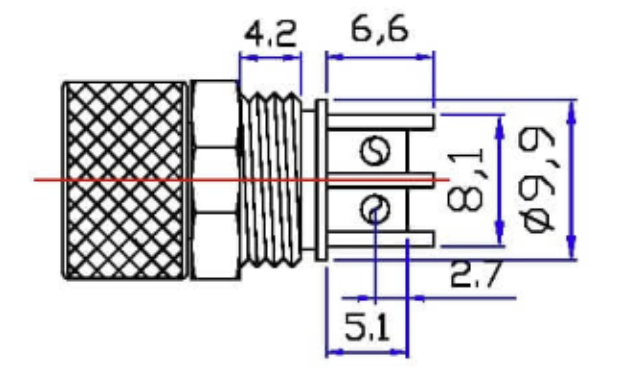

M8 Connectors: Compact and Efficient

M8 connectors are typically used in space-constrained environments where component density is a concern. These connectors are ideal for transmitting signal-level power in applications such as sensors, encoders, and low-profile actuators.

Typical use cases:

- Sensor integration in factory automation

- Control systems in compact enclosures

- Light-duty I/O in robotics or test systems

Key features:

- Metric Thread size: 8 mm

- Common pin counts: 3, 4, 5, or 8

- Sealing: IP67 or higher

- Coding: A-code (most common), others available for specific functions

If your application requires a small footprint and is limited to low current or data rates, M8 is often the better choice.

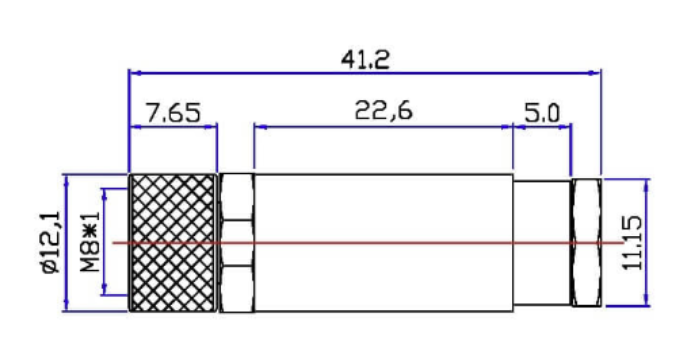

M12 connectors: Rugged Versatile

M12 connectors offer greater flexibility in signal and power delivery. With a larger form factor and wider range of codings, M12 is the preferred connector for Ethernet, fieldbus, and I/O interfaces in harsh environments.

Typical use cases:

- Industrial Ethernet up to 10 Gbps

- Power and signal in mobile machinery

- I/O modules in harsh environments

- Communications in medical diagnostic equipment

Key features:

- Metric Thread size: 12 mm

- Pin counts: 3 to 17

- Coding types: A, B, D, X, S, K, and more

- Sealing: IP67, IP68, IP69K options available

The M12 connector is often selected for applications where data rate, durability, or mixed-signal capabilities are required.

Comparison Chart: M8 vs M12

| Specification | M8 Connector | M12 Connector |

|---|---|---|

| Metric Thread Size | 8 mm | 12 mm |

| Common Pin Counts | 3 to 8 | 3 to 17 |

| Coding Types | A, B (limited availability) | A,B ,D, X, S, K, L, and more |

| Typical Use | Sensors, encoders, low-voltage signals | Ethernet, fieldbus, signal and power |

| Sealing Rating | IP67 | IP67 to IP69K |

| Size and Weight | Compact, lightweight | Larger, more robust |

| Data Capabilities | Basic signal and low-speed data | Up to 10 Gbps with X-coded versions |

Coding Matters

One of the most important design considerations is connector coding. Codings help prevent mismating and define what the connector is capable of transmitting. For example:

- A-coded: Common for standard sensors and 24V power

- D-coded: Supports Ethernet up to 100 Mbps

- X-coded: Designed for Gigabit Ethernet and beyond

- L-coded or K-coded: Used for power transmission

Choosing the wrong coding can result in signal failure or equipment damage. EI Sales works directly with design engineers to ensure compatibility and long-term system reliability.

Why OEMs Choose EI Sales for Interconnect Solutions

With over 40+ years of experience, EI Sales is more than a rep firm. We are a true extension of your engineering team. Our structure combines seven highly experienced outside sales engineers with a dedicated inside support coordinator, giving you responsive, technically fluent guidance from concept through production.

We represent only top-tier connector and component manufacturers. That means when you source through EI Sales, you gain access to vetted solutions that integrate seamlessly with your system architecture.

We also offer:

- U.S.-based cable and harness assembly

- Rapid prototyping and quick-turn electronic builds

- Support for compliance standards like ISO9001, ISO13485 and AS9100

- Expertise across board-level and subsystem design

Whether you're developing a sealed harness for an off-highway vehicle or designing an I/O panel for industrial automation, our team will match your project with the right connector family, materials, and termination method.

Ready to Specify the Right Connector?

If you're choosing between M8 and M12 connectors or building out a full interconnect strategy, EI Sales is here to help.

We provide engineering-driven component recommendations and manufacturing support that accelerates development without compromising quality.