Rapid PCB Prototyping

Why Speed and Precision Matter in PCB Prototyping

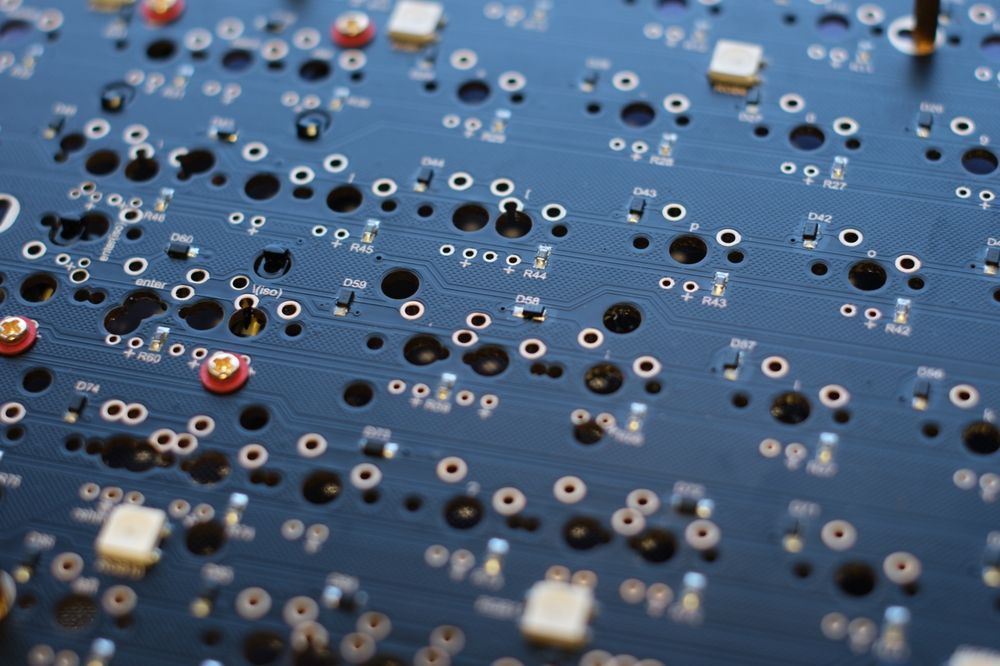

Prototyping plays a key role in keeping projects on track and avoiding delays. Fast access to functional boards helps engineers test early, fix issues, and move forward without production setbacks. Precision matters just as much. Tolerances, stack-up, and material choices must reflect final production needs, not just temporary test conditions.

That’s where EI Sales adds value. We work directly with design engineers and technical buyers to align requirements upfront. Through our trusted manufacturing partner, we offer fast, U.S.-based services that meet real-world design and performance targets.

U.S.-Based Quick-Turn Manufacturing

Timelines in product development are always tight. That’s why we connect OEMs to domestic quick-turn fabrication capable of delivering boards in as little as 24 hours, depending on build complexity. Working with a U.S. manufacturer means faster response times, clearer communication, and fewer shipping delays.

Prototypes are built using the same equipment, processes, and standards applied to production. This consistency helps reduce the number of board spins and keeps programs moving toward launch without disruption.

What our partners say

I just wanted to let you know that the five prototypes of the Glove 3.0 Main Board you built worked great. No errors and completely functional. Another exceptional job. Please let everyone know that this is why I use Ninja for our prototypes. I believe you have or will be receiving the P.O. for the remaining 25 units.

High-Performance Multilayer Builds

Complex designs rely on multilayer boards that manage dense routing, impedance control, and advanced materials without affecting performance. Our high-layer count builds meet the requirements of medical, aerospace, and industrial applications. These applications often involve complex layouts, thermal management needs, and strict material traceability.

We help engineers verify electrical performance, mechanical fit, and manufacturability across builds ranging from four to twenty-four layers before moving into production. The goal is to identify issues early and create a direct path to a reliable build that scales efficiently.

Precision Fabrication with Engineering Support

Tight tolerances, controlled impedance, and clean fabrication processes are standard for every project we handle. Our manufacturing partner brings decades of experience across complex board builds. Our engineering team gets involved early to review specifications, resolve constraints, and recommend improvements that strengthen overall build quality.

This hands-on approach reduces revisions and creates a smoother path into production. Each detail, including surface finishes and drill alignment, is reviewed to match your design intent. The result is a faster, more predictable prototype cycle with fewer disruptions and better alignment between design expectations and manufacturing results.

LATEST NEWS

Your PCB Prototyping Partner

EI Sales connects OEMs to fast, U.S.-based PCB prototyping through trusted manufacturing that delivers consistency, speed, and technical depth. We work closely with design engineers and procurement teams to keep projects moving without unnecessary delays. Quick quotes, direct communication, and early engineering input help maintain momentum and reduce risk.

You might be refining a first design or preparing for a production run; either way, we help you get the right board built the right way. We help you move faster, make informed design choices, and transition into production without delays or uncertainty. Talk to our team today about your next prototype.

Manufacturers Template Contact Us

We will get back to you as soon as possible.

Please try again later.