Electronics Manufacturing Services

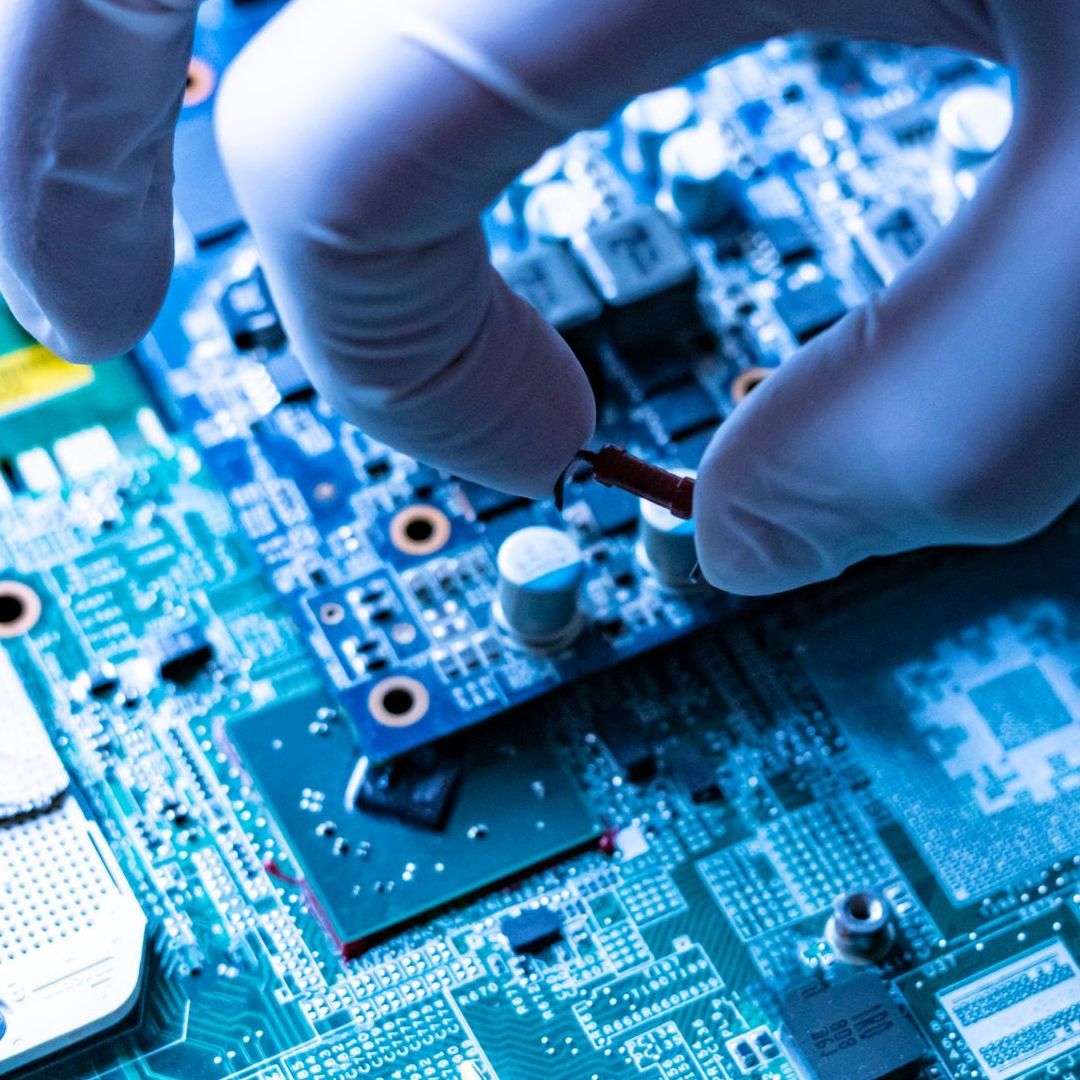

EI Sales connects OEMs to U.S.-based electronics manufacturing solutions for medical, aerospace, and industrial applications. Our partners specialize in low-to-mid volume production of complex assemblies, guiding teams through every stage of the build cycle. We link your project to manufacturing sources built for precision, compliance, and speed, backed by ITAR registration and top-tier certifications.

Specialized Markets & Industries

We work with OEMs in high-reliability and highly regulated sectors, where each build must meet strict technical, environmental, and regulatory criteria. Our partners produce assemblies that meet performance targets, maintain long-term durability, and ensure traceability across production runs.

Medical Electronics

Precision, cleanliness, and compliance define every stage of medical manufacturing. Our ISO 13485–certified facilities, operating to IPC Class III standards, support the production of surgical instruments, implantable devices, imaging systems, and patient-monitoring platforms.

End-to-end traceability and rigorous documentation are embedded throughout the build process, helping engineering and quality teams meet FDA requirements while accelerating validation and time to market.

Aerospace and Defense Systems

Electronics in flight and mission-critical systems must perform under extreme stress and environmental variability. We provide access to AS9100-D–certified, ITAR-registered manufacturing, with disciplined process controls that ensure consistency from prototype through full production.

Rigid-flex and flex assemblies built to IPC Class III standards are a core strength—especially where complexity, reliability, and traceability matter most. We also support cybersecurity and CMMC compliance requirements, helping protect both product integrity and program security.

Industrial Automation and Controls

Factory systems depend on rugged design and consistent signal paths. We align projects for motor controls, PLCs, HMIs, and sensing platforms using stable production processes and built-in test coverage to minimize downtime.

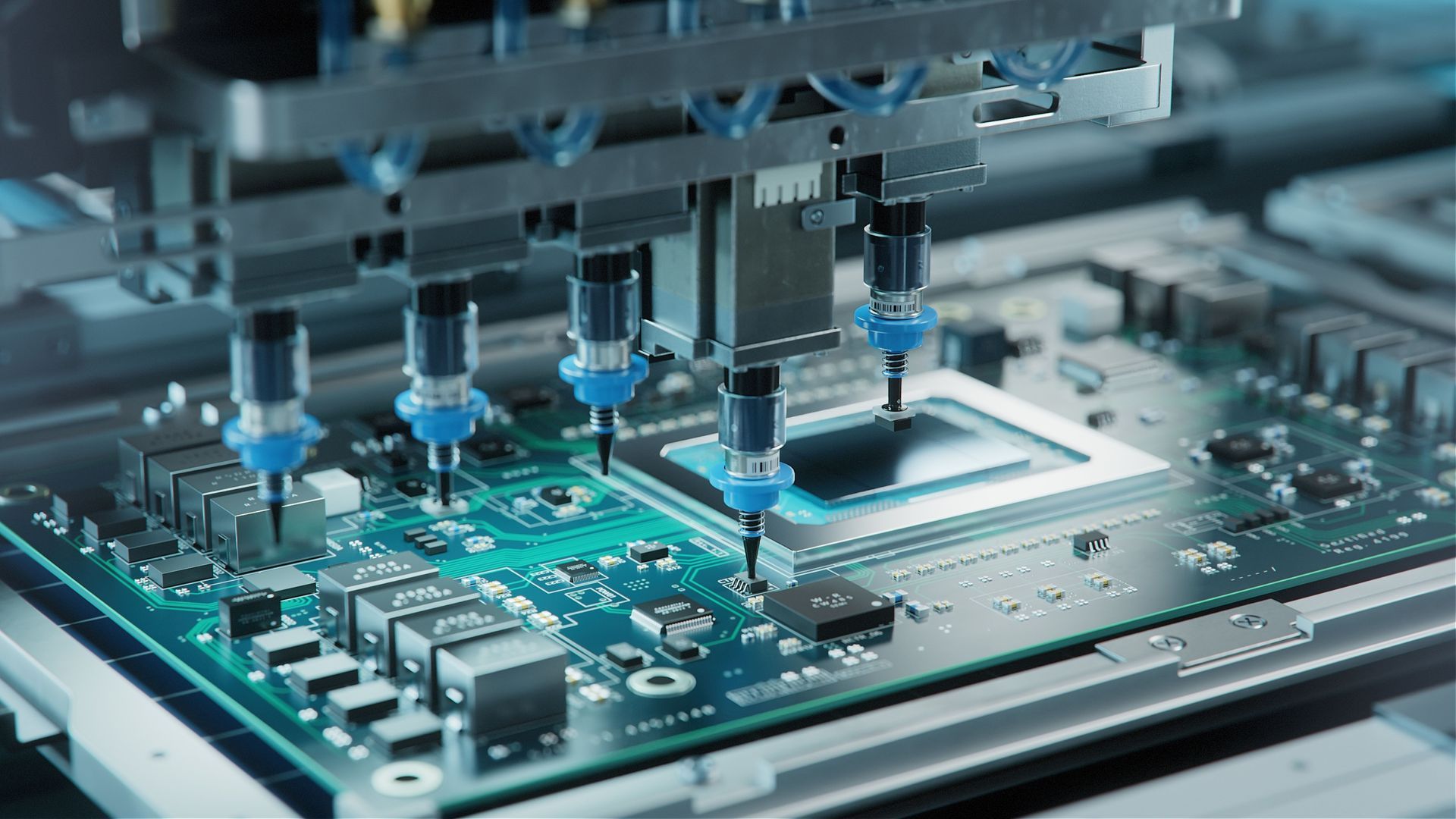

Emerging Technology Devices

Fast-growth OEMs in AI, robotics, and connected systems demand speed, flexibility, and precision. Advanced PCBs, RF technologies, and ultra-fine component geometries require specialized equipment and disciplined process expertise to ensure accurate placement and repeatable performance. From 01005 components to 2,000-ball BGAs, this level of complexity is routine for our teams.

We align your program with U.S.-based manufacturing partners engineered to adapt quickly to evolving specifications and accelerated development timelines.

End-to-End Electronics Manufacturing Capabilities

We manage full electronics manufacturing workflows—from rapid prototyping through system-level builds. Our partners handle complex, high-mix assemblies using tight process control, collaborative engineering input, and advanced inspection systems.

For early designs, we coordinate quick-turn prototyping to help teams move faster and uncover design risks early.

Automated Conformal Coating & Masking

Protective coatings are applied using automated systems for consistent coverage across sensitive circuitry. We coordinate selective masking, UV cure options, and material sets tailored for environments where moisture, dust, or chemical exposure may impact reliability.

Through-Hole and Mixed Technology Builds

We align each design to the best combination of manual and automated soldering. For mixed-technology boards, we coordinate flows that preserve mechanical strength and throughput without added delay.

PCB Overmolding Services

Overmolding enhances structural integrity and seals the board or subassembly. It's well-suited for portable equipment, field instrumentation, and any use case where ruggedization is a factor.

Full-System Integration and Final Assembly

We manage full box builds and system-level assembly, including chassis install, cable routing, and subsystem integration. Packaging and labeling can be configured to match finished goods requirements.

In-Circuit, Functional, and Flying Probe Testing

Each build includes testing aligned to its design. We coordinate ICT, flying probe, and functional test development for complex or low-volume projects to verify performance and reduce failure rates.

Automated Conformal Coating & Masking

Protective coatings are applied using automated systems for consistent coverage across sensitive circuitry. We coordinate selective masking, UV cure options, and material sets tailored for environments where moisture, dust, or chemical exposure may impact reliability.

Through-Hole and Mixed Technology Builds

We align each design to the best combination of manual and automated soldering. For mixed-technology boards, we coordinate flows that preserve mechanical strength and throughput without added delay.

PCB Overmolding Services

Overmolding enhances structural integrity and seals the board or subassembly. It's well-suited for portable equipment, field instrumentation, and any use case where ruggedization is a factor.

Full-System Integration and Final Assembly

We manage full box builds and system-level assembly, including chassis install, cable routing, and subsystem integration. Packaging and labeling can be configured to match finished goods requirements.

Partner with a U.S.-Based, ITAR-Registered EMS Provider

EI Sales connects OEMs to trusted electronics manufacturing teams across the U.S. Each facility is ITAR-registered and certified to ISO 9001, ISO 13485, and AS9100-D, meeting the needs of regulated and high-reliability builds.

From first articles through production, we stay involved to solve design issues, refine test strategies, and keep programs on track. Every engagement is structured to support documentation, audit readiness, and compliance requirements from NPI through release.

Ready to build in the U.S. with a certified EMS partner?

Contact EI Sales to get connected. Tell us what you're building, and we’ll help map the right path forward.

LATEST NEWS

Start Your Project Today!

Manufacturers Template Contact Us

We will get back to you as soon as possible.

Please try again later.