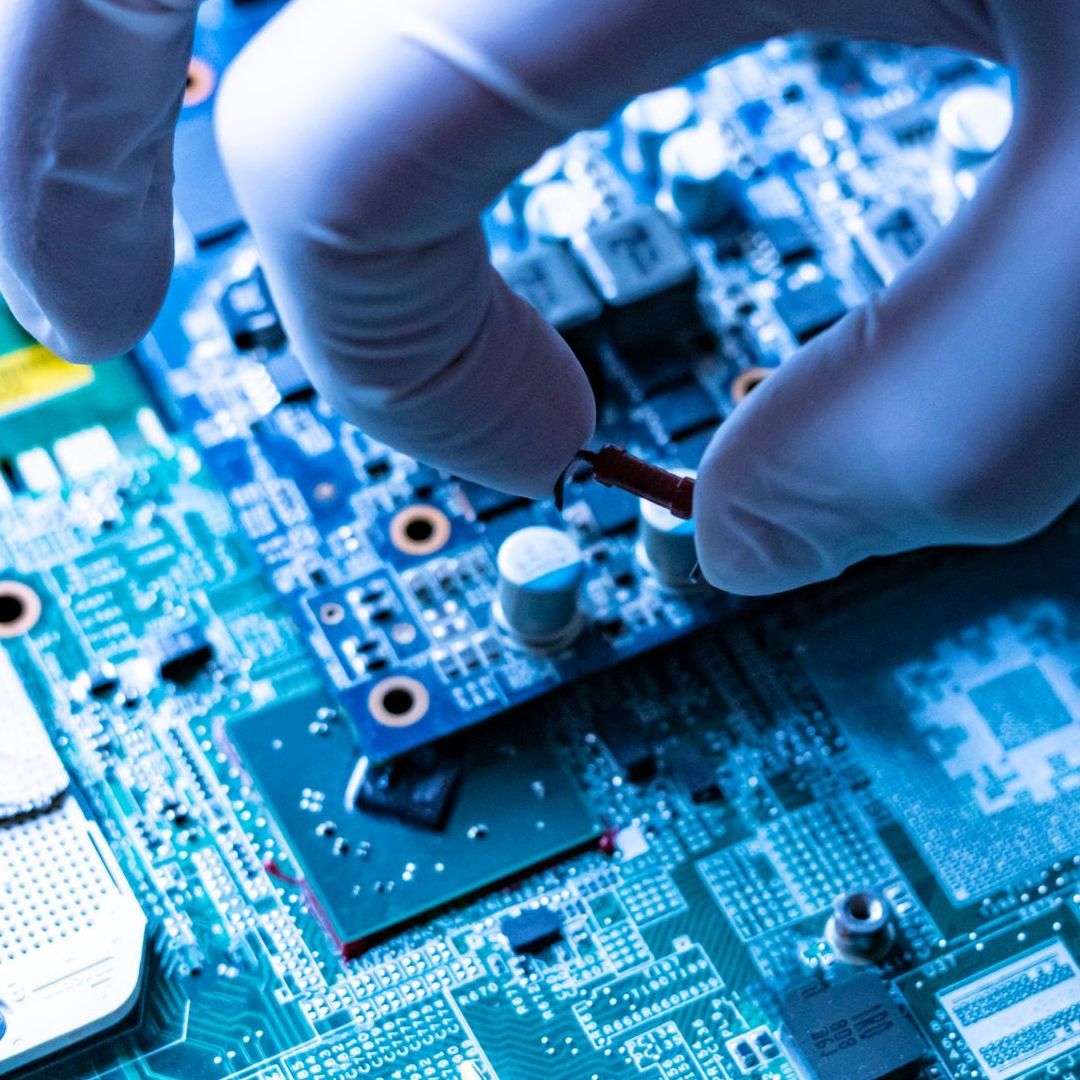

Conformal Coating & Masking Services

Conformal coating and masking protect sensitive circuitry from environmental exposure, extending product life and performance. EI Sales connects OEMs to automated coating services designed for repeatability, precision, and speed. We help teams build cleaner, more resilient assemblies using U.S.-based manufacturing partners and process controls aligned to the standards expected in medical, aerospace, and industrial environments.

Conformal Coating You Can Count On

Protective coatings are only effective when applied consistently. We coordinate conformal coating services that deliver uniform, selective coverage across every board. Using programmable application systems, our partners reduce human error and apply each coating to precise specifications while meeting IPC Class 3 and MIL-standard requirements.

For OEMs in aerospace, medical, and industrial sectors, coating consistency is tied directly to product reliability. Sensitive analog pathways, high-density layouts, and exposed interconnects demand a coating process that’s dialed in from the first run. We work with U.S.-based manufacturers who document each step, integrate inspection checkpoints, and verify material compatibility throughout production.

This level of process control helps protect assemblies in unpredictable environments without compromising accessibility, weight, or compliance.

Automated Masking Eliminates Guesswork

Selective masking is a critical part of any conformal coating process. Without it, coverage can interfere with connectors, test points, or components that must remain accessible. EI Sales works with manufacturing teams that use automated masking equipment and fixtures to block off keep-out zones with repeatable accuracy.

This approach eliminates variation between operators and replaces manual taping or boot placement with reliable, fixture-based coverage. Fixtures are designed to match your board’s geometry, so each run applies the same protection without added rework or clean-up.

Automation supports both mixed-technology and SMT assemblies by preventing coating bleed, maintaining access to functional areas, and reinforcing a clean, repeatable process.

Flexible Chemistries to Fit Your Environment

Our team connects OEMs to conformal coating services that support a wide range of chemistries, including acrylics, silicones, urethanes, and parylenes. Each material type offers distinct advantages based on operating temperature, moisture resistance, dielectric strength, and reworkability. We guide teams to select the right formula for their application and align the coating process to meet environmental and regulatory requirements.

Medical and aerospace assemblies often require low-outgassing coatings or materials compatible with sterilization and inspection processes. Industrial boards may need added chemical resistance or thermal stability. Every material choice is backed by a controlled application process, UV inspection where applicable, and complete documentation.

Our partners apply each chemistry using methods that preserve downstream processes and maintain service access where needed.

Integrated Coating, Inspection, and Test

Reliable coating depends on more than just material and application. EI Sales works with U.S.-based manufacturing teams that treat coating as part of a larger quality system. Coated boards are visually inspected under UV light and reviewed against process documentation before they advance to test.

Inspection stations are positioned in line to catch inconsistencies before the final build. Automated systems monitor flow rate, spray path, and cure cycle to prevent common failure modes like voids, pooling, or delamination. For assemblies requiring a functional test after coating, we help coordinate custom fixtures and coating profiles that allow for access to key test points.

This integrated approach supports faster release cycles, fewer rework loops, and consistent performance in the environments your product was designed for.

Start Your Project Today!

Manufacturers Template Contact Us

We will get back to you as soon as possible.

Please try again later.