Ceramic Capacitors

High-Reliability Ceramic Capacitors for Precision Electronics

EI Sales works with OEM engineers to source ceramic capacitors that meet the performance needs of medical devices, aerospace controls, and industrial automation equipment. Our sourcing process begins with a clear understanding of the application, addressing both signal stability in high-frequency circuits and the need for consistent operation in challenging environments where reliability is non-negotiable.

Through our vetted supplier network, we provide access to NP0, X7R, high-voltage, and automotive-grade options produced under documented quality control and traceability standards. These parts deliver stable capacitance, low loss, and high insulation resistance, supporting consistent electrical performance over extended lifecycles and across temperature variations.

Our technical sales team works closely with engineering groups to match electrical specifications, package formats, and environmental ratings to program requirements. This targeted approach shortens design cycles, supports compliance objectives, and helps maintain production schedules without compromising quality or manufacturability.

Broad Range of Dielectrics, Voltages, and Case Sizes

EI Sales sources a wide selection of dielectric materials, voltage ratings, and case sizes to meet varied performance and layout needs. This range supports designs as small as handheld diagnostic devices and as large as high-power industrial systems.

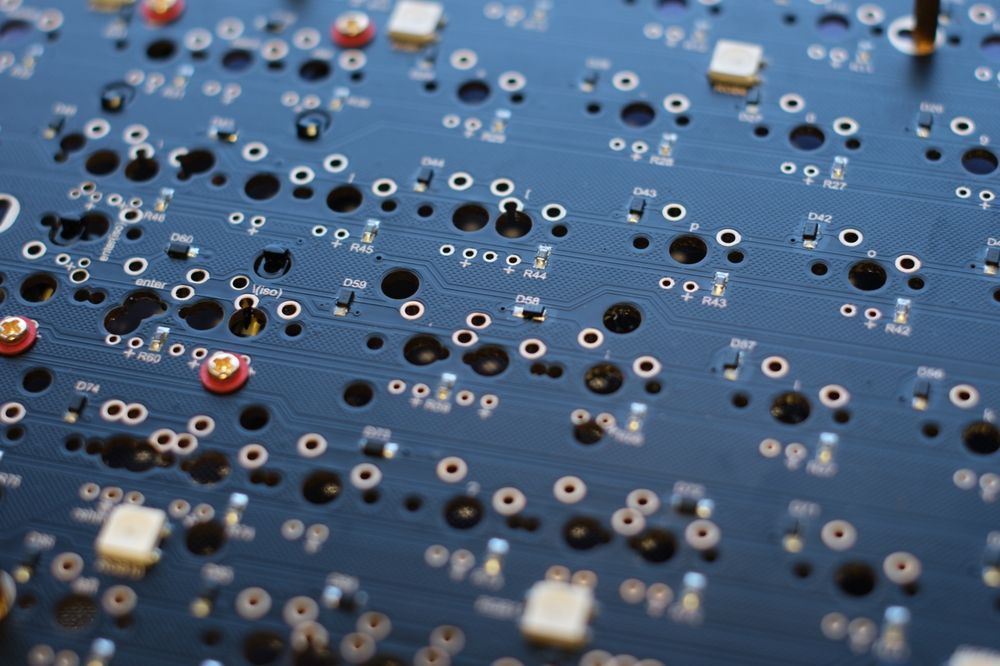

Available types include NP0 for precision signal control, X7R for stable operation over changing temperatures, and high-voltage versions for demanding industrial and aerospace applications. Case sizes include miniature 01005 formats suited for dense PCB layouts and larger packages designed for higher capacitance or higher voltage applications where space allows.

All components are manufactured to tight tolerances for electrical consistency and dimensional accuracy. Compatibility with automated pick-and-place processes helps reduce production risk, support high assembly yields, and keep throughput steady during scaled manufacturing runs.

What our partners say

I just wanted to let you know that the five prototypes of the Glove 3.0 Main Board you built worked great. No errors and completely functional. Another exceptional job. Please let everyone know that this is why I use Ninja for our prototypes. I believe you have or will be receiving the P.O. for the remaining 25 units.

Engineering Support for Specification and Design-In

Selecting the right component involves more than reviewing a datasheet. EI Sales supports engineers through performance evaluation, environmental assessment, and long-term reliability planning before recommending a part that fits the project’s unique requirements.

Our experience in medical, aerospace, and industrial programs allows us to identify products that meet electrical, mechanical, and regulatory standards. This process often includes reviewing temperature stability, voltage capacity, ESR values, mounting style, and board layout considerations to prevent downstream integration issues.

We coordinate directly with manufacturing partners to supply accurate technical data, soldering profiles, and application-specific recommendations. This collaborative work helps streamline prototyping, reduce engineering revisions, and support a smooth transition into full production without delays.

LATEST NEWS

Sourcing Solutions from Qualified Suppliers

Reliable sourcing depends on strong supplier relationships. EI Sales works with manufacturers that maintain a significant U.S. presence, recognized industry certifications, and proven delivery performance across multiple sectors. This approach supports OEM programs that require predictable lead times, stable product availability, and complete traceability.

Suppliers in our network often hold ISO 9001, ISO 13485, or AS9100 certifications, along with documented process controls suited for high-reliability markets. Each is evaluated for technical capabilities, manufacturing quality, and track record in the industries we serve, ensuring they can support both prototype quantities and volume production.

Beyond connecting OEMs to qualified lines, EI Sales monitors supply trends, coordinates shipment schedules, and serves as a single point of contact for technical and commercial needs. This reduces sourcing complexity, improves communication between teams, and keeps projects aligned during every stage, including early design and product launch.

Manufacturers Template Contact Us

We will get back to you as soon as possible.

Please try again later.