Whether you're prototyping a wearable medical device, developing a ruggedized industrial control unit, or optimizing an aerospace system, one decision can make or break your project: component selection. With thousands of parts to choose from and dozens of specifications to evaluate, knowing how to select the right electronic components isn’t just smart, it’s critical.

In this article, we’ll walk through key criteria to consider when evaluating and sourcing components for your design, helping you balance performance, reliability, cost, and availability.

Understand Your Application First

Before diving into datasheets and parametric filters, take a step back and define the functional requirements of your project. What problem is the device solving? What are the environmental conditions it will operate in? Will it require certifications like ISO 13485 or AS9100? These answers will shape the performance thresholds and durability expectations for every component you select.

Typical questions to ask include:

- What are the electrical load requirements?

- Are there size or weight constraints?

- Will the product operate in extreme temperatures or humid environments?

- Does the design need to meet EMC or ESD protection standards?

- How long is the product life cycle expected to be?

The more specific your requirements, the easier it will be to narrow down your options later.

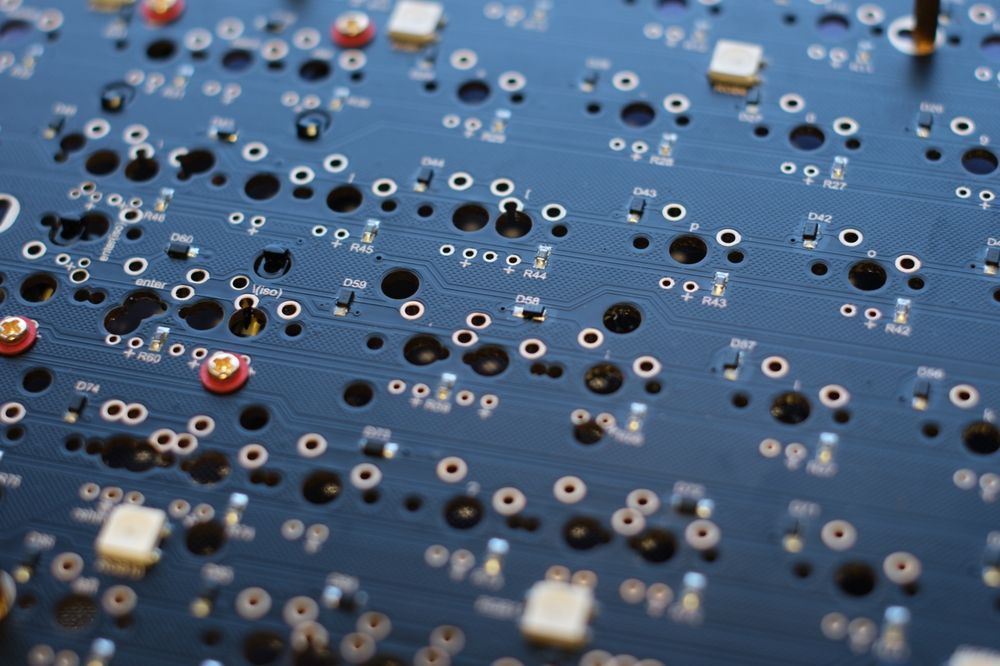

Evaluate Electrical Performance Specifications

Once you’ve defined the application's needs, focus on the technical specs. For passive components like resistors or capacitors, consider voltage ratings, tolerance, temperature coefficient, and package size. For semiconductors, pay attention to parameters like forward voltage, current handling, switching speed, and thermal resistance.

Common component classes to evaluate include:

- Microprocessors & Microcontolers: x86, ARM, RISC-V, MIPS

- Analog Signal Chain: A/D, D/A, Ref, VReg’s, Op Amps

- Power semiconductors: MOSFETs, IGBTs, diodes

- Capacitors and resistors: Ceramic, tantalum, film, precision resistors

- Connectors and switches: Rated voltage, mating cycles, contact materials

- Sensors: Accuracy, response time, signal type (analog or digital)

- Displays and LEDs: Viewing angle, brightness, interface compatibility

Matching performance requirements to spec sheets is not just about checking boxes, it’s about building in long term reliability and minimizing redesign risks.

Consider Long Term Availability

It’s easy to focus on performance and cost, but many projects get delayed, or completely derailed, by parts going end of life (EOL) or out of stock. Always check lifecycle status through manufacturers or authorized distributors. Avoid niche components with unclear sourcing channels unless there’s a valid reason to use them.

Tip: If you’re designing a product expected to stay in market for 5 years or more, build in supply chain resiliency. Favor components from manufacturers with a track record of longevity and consistent delivery.

Add Multiple Vendors to Your Bill of Materials

Whenever possible, choose parts with multiple approved sources and ensure these are added to the Approved Vendor List (AVL). This allows your supply chain team to select the best option for both price and delivery, while reducing supply chain risk during times of allocation.

Passive components such as capacitors, resistors, connectors, diodes, LEDs, and power products often have second-source options from many vendors. By contrast, semiconductors—including FPGAs, microcontrollers, microprocessors, analog signal chain components, and sensors—rarely have true second sources. However, they may have alternatives in speed grades, packages, or families that can be added to the AVL. Doing so provides your supply chain team or contract manufacturer with more flexibility and resilience in times of shortage.

Determine what parts are “Registerable” per the Supplier

When a part is described as “registerable,” it means it can be formally recorded with a distributor, giving that distributor access to preferred pricing. Suppliers use registrations to reward distributors who actively support their products at a customer account—through recommending parts, providing samples, or assisting in design-in efforts.

The advantage of part registration is that it encourages distributor support and technical engagement. The drawback is that it can create an uneven playing field in production pricing, especially if your supply chain is not aligned with the distributor who supported the original design.

Registrable parts are often unique due to specific features, which may limit flexibility in pricing and availability. For example, one distributor may have physical inventory but not hold the registration. In that case, you may face the choice of paying a higher price to get the part immediately or waiting until the registered distributor receives stock.

To avoid surprises, it’s important to ask your supplier or distributor if a part is registerable. Your supply chain team or electronic manufacturing services (EMS) provider also needs this information to secure the best pricing and ensure consistent availability.

Don’t Overlook Quality and Compliance

Especially in medical, aerospace, and industrial sectors, quality standards matter. Selecting components certified to relevant standards, such as ISO, RoHS, UL, or MIL SPEC, can reduce testing requirements later and help you pass regulatory review faster.

Also, consider how the component fits into your broader quality strategy:

- Is the component traceable to a specific lot or batch?

- Can it be sourced from ITAR registered or domestic suppliers?

- Is it compliant with environmental standards?

Selecting parts that align with industry certifications adds confidence to your design and builds trust with stakeholders.

Use Tools and Resources Wisely

There are plenty of component selection tools available, from Digi-Key, Mouser, Arrow, Avnet, Future and others, that let you filter parts by parameter, compare options, and download models for simulation. Don’t hesitate to use these tools in conjunction with:

- Manufacturer application notes

- Reference designs

- Webinars or training sessions

- Silicon Expert

- Octopart

- Findchips

- Component evaluation boards

Even better, reach out to manufacturers’ representatives or application engineers for guidance when you’re between part options. Their insight can help you avoid common pitfalls or uncover better alternatives.

Prototype, Test, Iterate

Even the best theoretical selection needs validation. Order evaluation quantities and test them in real world conditions. Pay attention to:

- Signal integrity under load

- Heat dissipation

- Mechanical fit and connector mating

- Solderability and footprint accuracy

Use this stage to refine not only the part choices but also your bill of materials strategy, grouping parts from preferred vendors, reducing unique component counts, and preparing for volume sourcing.

Make Confident Component Choices That Power Success

Choosing the right electronic components is one of the most impactful decisions in your product development cycle. It influences performance, reliability, compliance, cost, and manufacturability. By taking a structured approach, starting with application needs, weighing performance specs, confirming compliance, and validating through testing, you set your project up for long term success.

Still, even the most experienced engineering teams benefit from guidance. That’s where EI Sales comes in. With over 39 years of experience and a technically fluent team that supports OEMs from concept through production, we’re more than a rep, we’re your solutions partner.

If you're looking for support with sourcing, design integration, or navigating complex certification requirements, connect with EI Sales today. Let’s build smarter, faster, and with confidence, together.