Sustainability and electronics are becoming increasingly connected as OEMs face mounting pressure to reduce environmental impact without compromising performance. Each stage of the production process offers opportunities to reduce resource use, minimize waste, and increase product longevity. These changes stem from more than market pressure. Customers in aerospace, medical, and industrial sectors now expect smarter, cleaner, and more sustainable manufacturing practices.

The Growing Importance of Sustainability in Electronics

Environmental considerations are influencing more purchasing decisions across the electronics supply chain. OEMs are now weighing sustainability alongside cost, performance, and lead time. For engineers and procurement teams, that means selecting suppliers and contract manufacturers who can meet environmental goals without adding complexity.

This shift is especially visible in sectors like aerospace, medical, and industrial automation, where product development cycles are long and regulatory pressure continues to grow. Companies are being asked to document carbon impact, reduce hazardous materials, and adopt cleaner production processes.

Sustainability and electronics are no longer separate conversations. In many RFQs, documentation of environmental practices influences supplier selection. The ability to offer transparent sourcing, efficient designs, and low-waste assembly processes has become a strategic advantage for manufacturers competing for long-term OEM partnerships across industries focused on compliance and longevity.

Designing for Durability and Long Product Life

One of the most effective ways to support sustainability in electronics is through durable design. When products last longer, fewer materials are consumed over time, and the environmental impact of replacements and repairs is reduced. This starts at the engineering level through selecting robust components, designing for thermal efficiency, and minimizing points of failure.

In sectors like medical and aerospace, reliability already drives most design decisions. Aligning those same principles with environmental goals doesn’t require a shift in mindset, just a broader awareness of the impact. Design teams can extend product life through smart layout, protective enclosures, and materials that withstand harsh conditions.

Fewer failures in the field lead to fewer scrapped assemblies and less electronic waste. A longer product lifecycle benefits both the bottom line and sustainability goals without sacrificing performance.

Sourcing Eco-Friendly Components and Materials

Material selection plays a significant role in sustainable electronics production. Engineers and sourcing teams are increasingly favoring components that meet environmental certifications such as RoHS or REACH, while also looking at packaging, recyclability, and country of origin. These factors contribute directly to a reduced carbon footprint and improved supply chain transparency.

Choosing eco-friendly substrates, lead-free solder, and halogen-free laminates helps reduce the environmental impact of the final assembly. Vendors that offer documentation on lifecycle impact and responsible sourcing practices are gaining preference among OEMs focused on long-term sustainability.

Supply chain decisions affect more than just price and availability. When components are sourced responsibly, manufacturers reduce exposure to environmental risks and align better with customer values. These choices reinforce a commitment to cleaner production and support system-wide improvements without compromising electrical or mechanical performance. This has become increasingly important for

distributors and suppliers who need to meet both environmental and regulatory expectations.

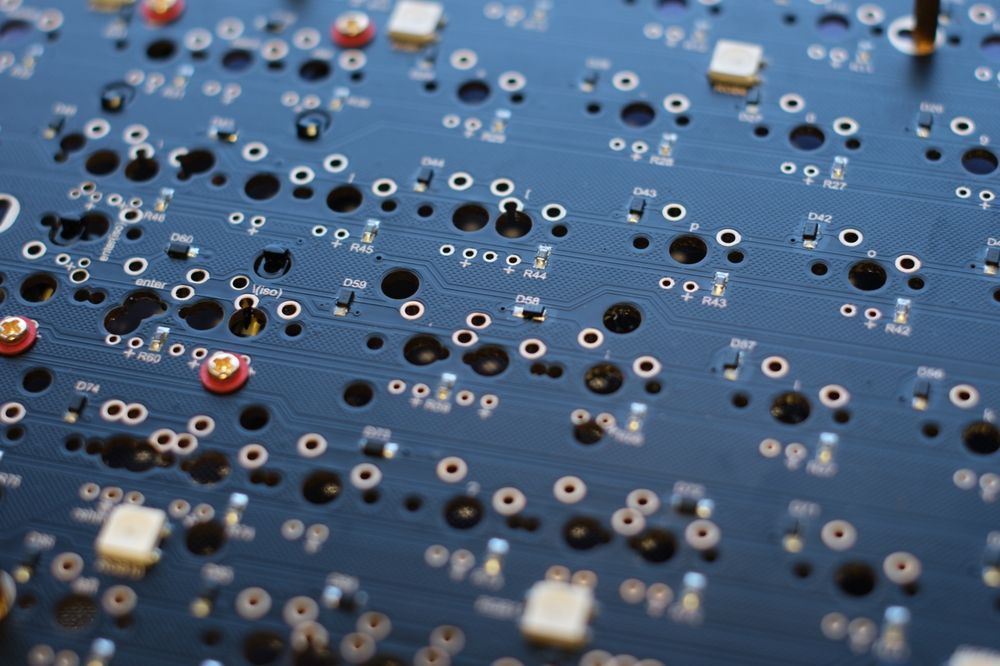

Reducing Waste in PCB Fabrication and Assembly

Waste reduction starts well before a product reaches the end of its life. In PCB fabrication and assembly, manufacturers can cut material waste through tighter panel utilization, better yield rates, and smarter stencil design. Modern surface mount processes also reduce the need for excessive solder and adhesives, lowering chemical use without affecting reliability.

Process control plays a big role. Precise placement, automated inspection, and real-time tracking all help catch issues early and prevent rework. Fewer rejected boards mean less scrap, lower energy use, and a cleaner shop floor.

OEMs working toward sustainability goals look for partners who can keep waste low while maintaining consistency across builds. Waste reduction is no longer a bonus. It is now a standard for electronics manufacturers focused on performance and environmental responsibility.

Energy Efficiency in Manufacturing Operations

Energy use is one of the most measurable ways electronics manufacturers impact the environment. Reducing electricity consumption during assembly, testing, and inspection not only lowers costs but also supports broader sustainability targets. Facilities that use energy-efficient reflow ovens, low-power lighting, and optimized HVAC systems reduce strain on the grid while improving process stability.

Automation can also play a role. When machines run efficiently and downtime is minimized, less energy is wasted between production cycles. Simple changes like shutting off idle equipment or adjusting temperature setpoints can make a meaningful difference over time.

OEMs are paying closer attention to how their partners manage energy. Manufacturers that prioritize energy-efficient systems stand out in supply chain evaluations, especially when long-term sustainability requirements are part of the project scope.

The Role of Localized Manufacturing in Reducing Carbon Footprint

Shorter supply chains support lower emissions. When components and assemblies are sourced and built closer to the end user, less fuel is consumed in transit, and fewer logistics steps are required. Localized manufacturing eliminates the need for long-haul shipping, air freight, and overseas warehousing. All of these contribute to higher carbon output.

For OEMs in medical, aerospace, and industrial sectors, working with domestic partners reduces risk while supporting environmental targets. Proximity allows for faster communication, quicker iterations, and fewer delays, which translates into fewer expedited shipments and less waste.

U.S.-based manufacturers that provide in-region support across sourcing, assembly, and delivery offer both speed and sustainability. Local production reduces emissions. It also improves supply chain reliability and supports growing customer expectations around sustainability and electronics across the territories we serve.

How EI Sales Supports Sustainable Production Goals

EI Sales works alongside OEMs to reduce environmental impact through every phase of product development. Our Central U.S.-based manufacturing services help eliminate the need for long-distance logistics, allowing for faster turnaround and lower emissions. We support efficient builds through smart layout guidance, low-waste assembly methods, and access to components that meet RoHS and REACH compliance.

For teams focused on durability, we offer design support aimed at long product life and fewer field failures. Our facilities maintain ISO 13485 and AS9100 certifications, reinforcing quality and consistency across sectors that value sustainability and performance.

OEMs building medical equipment or industrial control systems can rely on EI Sales for cleaner production, reliable delivery, long-term value, and ongoing support throughout the entire product lifecycle.