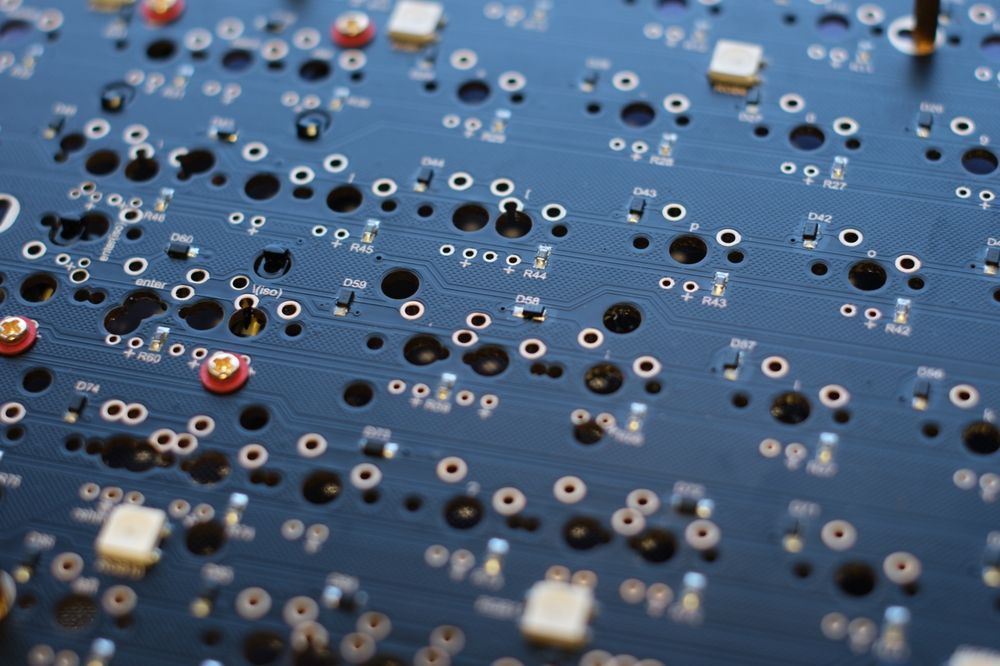

Surface Mount Technology (SMT) refers to the method of mounting electronic components directly onto the surface of a printed wiring board. Unlike through-hole technology, which requires drilled holes for leaded parts, SMT relies on smaller, leadless components that are placed and soldered onto pads.

This method allows for higher circuit density, faster assembly, and improved electrical performance. These advantages make SMT a preferred approach for building compact, reliable electronics used in medical devices, aerospace systems, and industrial automation.

Why SMT Matters for High-Reliability Applications

Medical, aerospace, and industrial automation sectors operate in environments where failure is not an option. Each board, each component, and each connection must perform consistently under stress, vibration, and varying temperatures. Surface Mount Technology enhances this reliability by reducing physical strain on solder joints and enabling tighter, more controlled assembly.

Because SMT parts are smaller and have no long leads passing through a board, they create fewer mechanical stress points and improve electrical performance. This translates into stronger signal integrity and more consistent operation in dense, multi-layer circuits. The precise placement and reflow soldering used in SMT also reduce human error and variability.

OEMs building smarter, smaller, and more rugged systems choose SMT to meet both design and compliance requirements. In high-reliability sectors, SMT remains the most dependable option for meeting performance goals and regulatory expectations across a range of

industries that demand consistency and control.

From Prototype to Production: The SMT Process

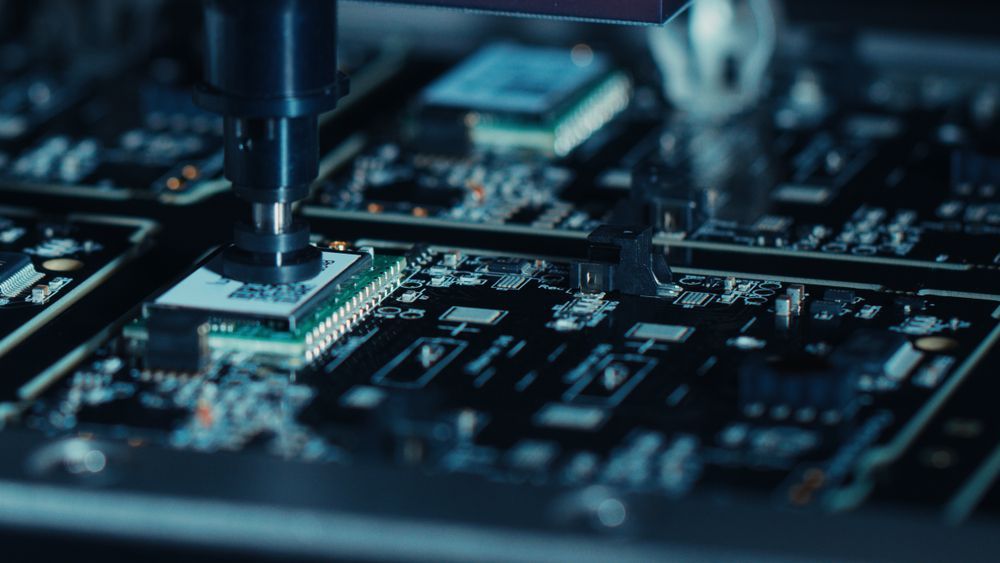

The SMT process begins with solder paste application using precision stencils that match the circuit board’s pad layout. Once applied, components are placed by high-speed pick-and-place machines that position each part with sub-millimeter accuracy. The assembly is then passed through a reflow oven, where controlled heat melts the solder paste and forms permanent electrical and mechanical connections.

This same process applies to small-batch prototypes, allowing engineers to validate form, fit, and function without retooling for volume. That helps catch design issues early and shortens iteration cycles. SMT’s compatibility with both quick-turn prototyping and volume production makes it well-suited for OEMs scaling toward commercial release.

Repeatability and control in stencil printing, placement, and reflow ensure consistent quality across all builds, starting at concept and continuing through full production.

SMT Solutions You Can Expect from EI Sales

EI Sales guides every phase of SMT assembly, from early design input to full production. OEMs count on our team to accelerate development through fast, accurate prototyping and dependable builds. Our quick-turn capabilities, including 24-hour turnaround, support teams that need fully assembled circuit boards without delay.

Our in-house manufacturing covers surface mount, mixed technology, and box build assembly. We work directly with engineers to identify suitable components, address layout challenges, and keep timelines on track. Our SMT lines are configured for medical, aerospace, and industrial work, and all assemblies are backed by ISO 13485 and AS9100 certifications.

We collaborate closely with both OEMs and

distributors to align on specifications, reduce lead times, and strengthen long-term production goals across

territories we serve.

When you need precision, repeatability, and support that matches the pace of your development cycle, EI Sales is ready to deliver. For OEMs who value trust, speed, and technical fluency, our SMT technology capabilities are built to perform.