Electronic switches give engineers control over power, signal flow, and user interaction in electronic systems. They influence performance and reliability in medical instruments, industrial machinery, and aerospace equipment. Selecting the right switch means balancing actuation style, electrical rating, sealing, and mounting so the component integrates smoothly into the design and supports long-term functionality across multiple applications and

industries.

Understanding the Role of Switches in Electronic Design

Switches are small components that carry a big responsibility in electronic systems. They control current flow, initiate functions, and provide tactile feedback that connects users to devices. A well-chosen switch helps engineers balance safety, efficiency, and user experience in equipment ranging from medical monitors to industrial controllers.

The wrong choice can create design bottlenecks or reduce system reliability. Actuation force, electrical load, and environmental sealing all influence how a switch performs over time. Each of these factors should be evaluated early in the design process.

Design groups comparing options should look at how each switch type interacts with circuit requirements, user expectations, and physical constraints inside the finished assembly. Careful attention to these details leads to smoother integration and dependable long-term operation.

Common Types of Electronic Switches

Switch types serve distinct purposes, and selecting the right one starts with understanding their strengths. Some of the most common types of electronic switches include:

Tactile Switches

Compact, surface-mount options that delvier sharp feedback for handheld devices, medical instruments, and consumer interfaces.

Rocker Switches

Panel-mounted switches recognized for ergonomic operation and durability, often used in industrial equipment, HVAC panels, and transportation dashboards.

Pushbutton Switches

Available in momentary or latching styles, offering reliable actuation in instrumentation, control panels, and aerospace systems.

Toggle Switches

Rugged designs suitable for test systems, industrial consoles, and vehicle controls where clear actuation and long service life are important.

What to Look for When Choosing an Electronic Switch

Selecting a switch involves more than finding the right size and feel for the application. Engineers must consider how the part will perform throughout the product’s lifecycle and under real-world conditions. The following factors often determine whether a switch is a strong match for the design:

Actuation Style

Momentary, latching, or tactile response depending on user interaction.

Rocker Switches

Voltage and current capacity suited to system requirements.

Sealing

IP-rated protection for equipment exposed to dust, moisture, or contaminants.

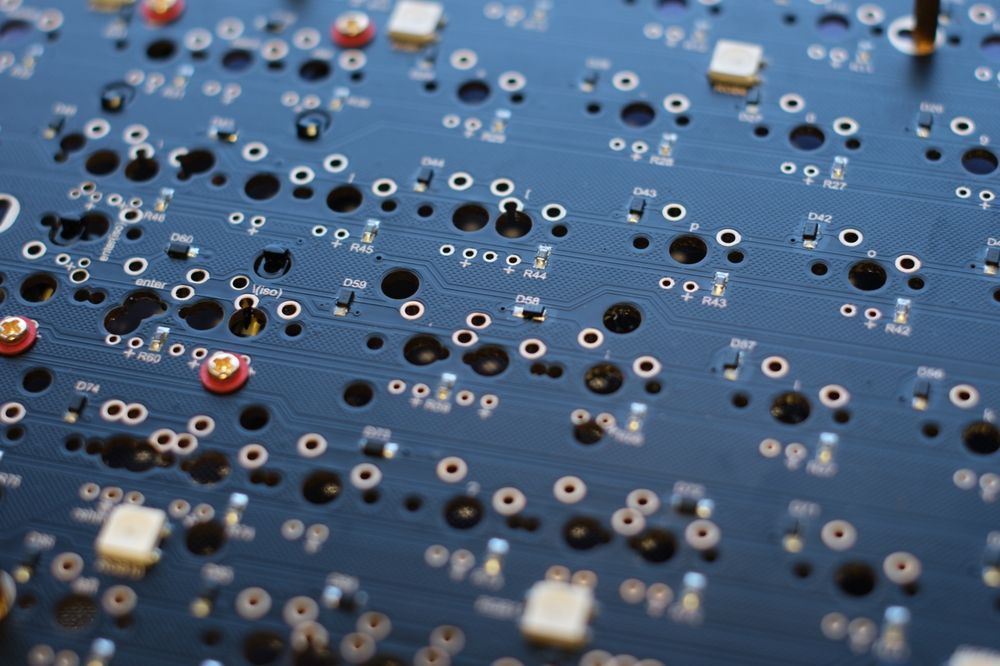

Mounting Method

PCB, panel, or subminiature styles that align with space and layout constraints.

Lifecycle Performance

Number of cycles expected before replacement or failure.

Try Before You Decide

A switch’s feel defines your customer’s experience. It’s the first tactile connection between your product and the person using it… and let’s face it, that first impression matters. From the resistance of the button to the smoothness of actuation, every detail communicates quality, durability, and brand personality.

EI Sales can get a sample kit in your hands so you can evaluate a variety of e-Switch options firsthand. Whether your application demands rugged performance, water resistance, or sleek aesthetics, you’ll quickly see (and feel) which switch best aligns with your product’s goals.

Reliable Switch Sourcing with EI Sales

A switch only adds value when it arrives on time, integrates cleanly, and performs as expected in the field. EI Sales connects OEMs to reliable types of electronic switches through trusted manufacturer partnerships and decades of engineering-focused sales experience. Our team also collaborates closely with distributors to give customers fast, consistent access to stocked parts.

We manage every stage of development, from early part selection to prototype assembly and full production sourcing. Local representation in the territories we serve, combined with U.S.-based resources, shortens communication cycles and provides direct access to technical expertise when needed most.

Engineers working in medical, industrial, and transportation programs gain a partner that simplifies sourcing and accelerates delivery of dependable switch solutions to market without unnecessary delays.