Printed Circuit Boards are the backbone of nearly every modern electronic system. From life-saving medical devices to ruggedized control modules in off-road vehicles, the humble PCB is evolving to meet increasingly complex demands. At EI Sales, we work at the intersection of design, manufacturing, and engineering, and we are seeing firsthand how PCB innovation is transforming the future of electronics.

As Original Equipment Manufacturers look to reduce size, increase functionality, and ensure reliability in harsh environments, PCB design is becoming a key differentiator, not just a support function. Here’s where the future is headed, and how EI Sales is helping engineers and procurement leaders stay ahead of the curve.

1. Miniaturization with High-Density Interconnects

Device real estate is shrinking, but performance expectations continue to grow. High-Density Interconnect (HDI) technology allows engineers to pack more functionality into smaller form factors. This includes microvias, laser-drilled via structures, and stacked via configurations that enable more complex routing in limited space.

We are seeing demand for 10, 12, and even 24-layer HDI boards in industries like aerospace and medical diagnostics. These boards offer signal integrity and reduced electromagnetic interference while supporting high-speed data transfer.

EI Sales supports advanced HDI bare board sourcing and layout guidance. When signal integrity and board density are mission-critical, our team is ready to help from the earliest design phase.

2. Rigid-Flex and Flex Circuits for 3D Designs

As enclosures become more compact and unconventional in shape, rigid-flex PCBs are emerging as a go-to solution. These hybrid boards combine the durability of rigid boards with the flexibility to bend around tight corners or inside small housings.

Rigid-flex designs are gaining ground in wearables, implantable medical devices, avionics, and industrial control panels where movement, vibration, and space limitations are real concerns. These designs reduce connector use, improve reliability, and lower overall system weight.

Our network includes suppliers skilled in rigid-flex layout and manufacturing. EI Sales helps customers navigate design rules, materials selection, and prototyping for these advanced assemblies.

3. Materials that Perform in Harsh Environments

Standard FR-4 laminate is no longer sufficient in many applications. As end-use environments become more extreme, think high heat, chemical exposure, or wide temperature swings, engineers are turning to advanced materials like polyimide, Rogers, and ceramic-filled substrates.

Applications in aerospace, space, and oil and gas , for example, require materials with higher thermal conductivity and low dielectric loss.

These materials ensure long-term performance in power electronics, RF circuits, and sensors.

EI Sales offers access to a wide range of specialty laminates and can advise on sourcing partners that meet IPC Class 3 and MIL-SPEC standards.

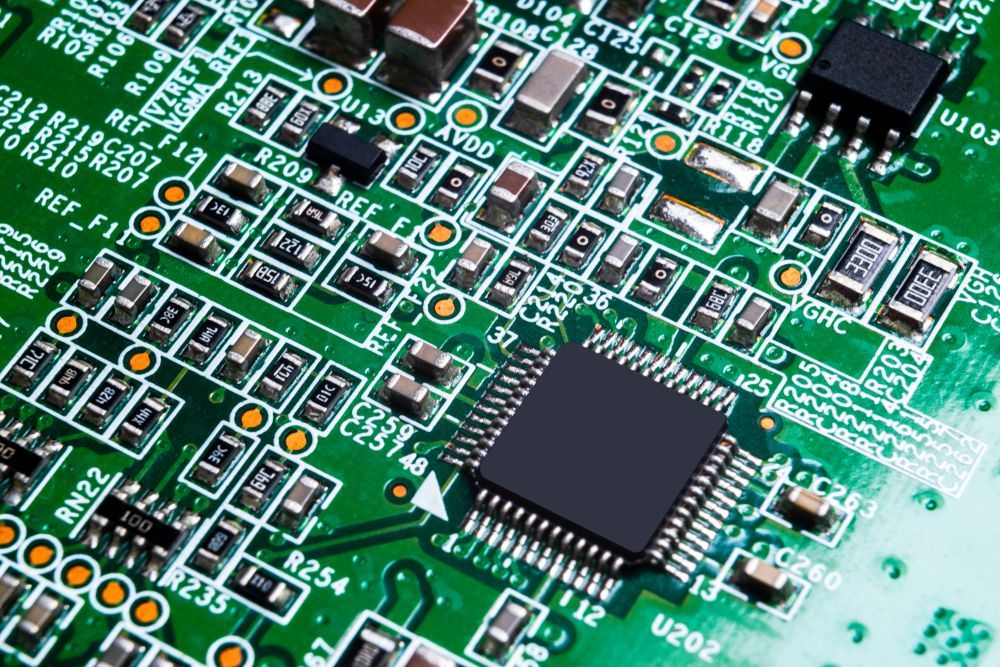

4. Integration with Embedded Components

Embedding passive and active components directly into the PCB substrate is an emerging trend that reduces board height, shortens signal paths, and enhances thermal management. Embedded component technology is particularly useful in high-speed applications where space and performance are at a premium.

We anticipate this approach will continue to grow in sectors like defense electronics and portable medical devices, where space constraints are constant and performance cannot be compromised.

While still a specialty process, EI Sales can connect customers with fabricators experienced in embedded component design and production.

5. Smarter Prototyping and DFM Collaboration

Design for Manufacturability (DFM) is no longer a late-stage checklist. It is now part of early-stage collaboration between design engineers and manufacturing partners. EI Sales offers prototype pcb assembly suppliers with turnaround as fast as 3-4 days. Our platform is built with US PCB manufacturers that offer DFM support and dedicated lines for prototyping. We help engineers iterate faster while ensuring designs are production-ready.

6. Quality, Compliance, and Cybersecurity

As PCB complexity increases, so do the requirements for traceability, compliance, and secure manufacturing. Medical and aerospace customers demand ISO 13485, AS9100, and ITAR registration. And with connected devices becoming standard, cybersecurity is now part of the design conversation. Military build documentation must be handled carefully using secure systems and processes to ensure confidentiality.

EI Sales operates with robust quality systems and regulatory certifications, ensuring every board and assembly meets the most rigorous standards. Our in-house design services also include support for cybersecurity compliance and documentation to help clients achieve certification with confidence.

Preparing for What Comes Next

The future of PCB design is no longer just about connecting traces, it’s about enabling smarter, smaller, more reliable systems that integrate seamlessly into their environments. It’s about designing with manufacturability, testability, and compliance in mind from day one.

At EI Sales, we provide solutions that span bare board fabrication, prototype assembly, cable and harness builds, and full turnkey manufacturing. Whether you are rethinking the layout of a compact medical device or scaling up production for a rugged industrial system, our platform gives you the edge.