Precision injection molding is a specialized manufacturing process that produces plastic components with exceptional accuracy, tight tolerances, and consistent quality. Unlike standard injection molding, which is suitable for general purpose parts, precision molding is engineered for applications where even minor deviations can compromise functionality or safety.

This guide explores the fundamentals of precision injection molding, its advantages, applications, and how to determine if it's the right solution for your project.

Understanding Precision Injection Molding

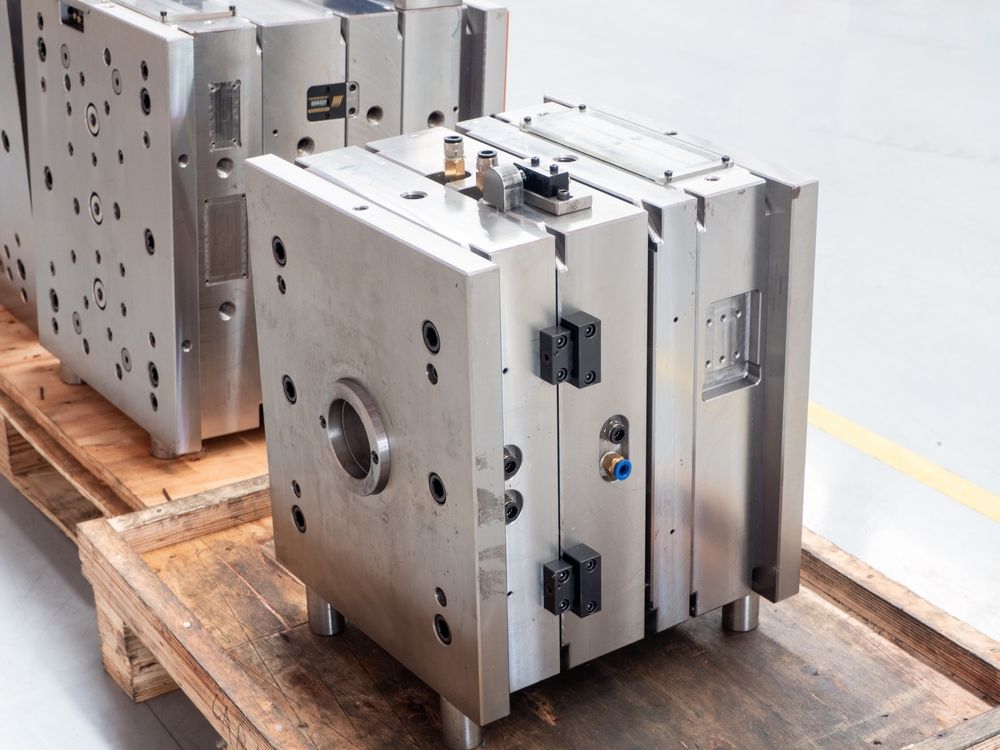

At its core, precision injection molding involves injecting molten plastic into a meticulously designed mold cavity under controlled conditions. The goal is to produce parts that meet exact specifications with minimal variation between units. This process is essential for industries where component consistency and reliability are paramount.

Key Features of Precision Injection Molding

- Tight Tolerances: Precision molding achieves dimensional tolerances as tight as ±0.001 inches (±0.025 mm), ensuring each part conforms to exact design requirements.

- Complex Geometries: The process accommodates intricate designs, including thin walls, undercuts, and micro features, without compromising structural integrity.

- Material Selection: High performance thermoplastics like PEEK, LCP, and Ultem are commonly used, offering superior mechanical properties and thermal stability.

- Advanced Tooling: Molds are crafted from hardened steel or aluminum using CNC machining and EDM processes, ensuring longevity and precision.

- Process Control: State of the art injection molding machines with real time monitoring systems maintain consistent temperature, pressure, and injection speed throughout the production cycle.

Advantages of Precision Injection Molding

- Consistency: Ensures uniformity across large production runs, reducing variability and defects.

- Efficiency: Minimizes material waste and post processing requirements, leading to cost savings.

- Scalability: Ideal for both low and high volume production, adapting to project needs.

- Quality: Delivers superior surface finishes and structural integrity, meeting stringent industry standards.

Applications Across Industries

Precision injection molding is integral to various sectors, including:

- Medical Devices: Surgical instruments, diagnostic equipment, and implantable components.

- Automotive: Engine components, sensor housings, and interior fittings.

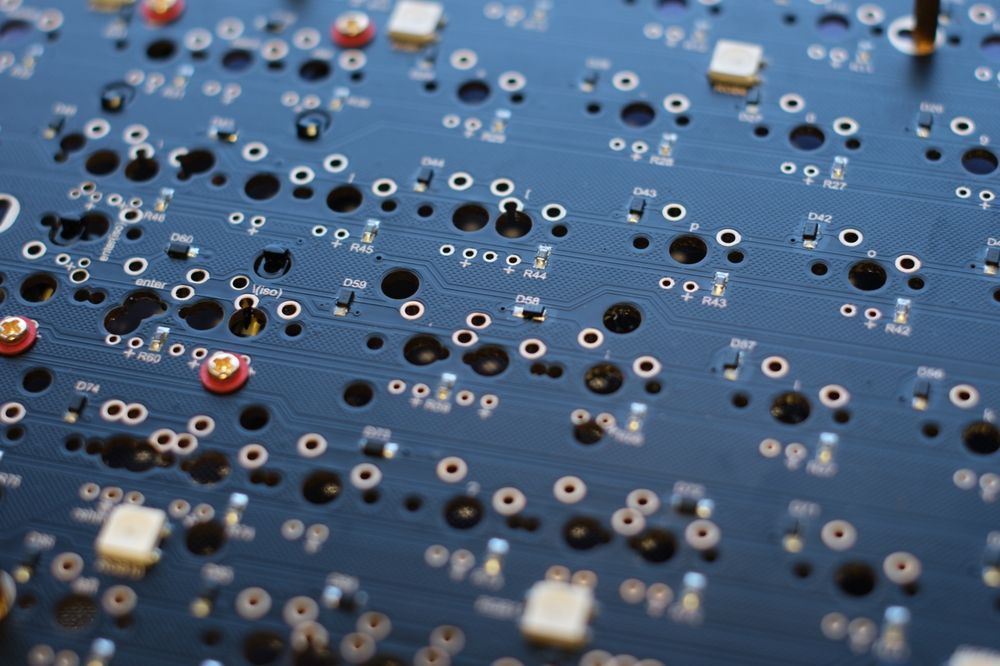

- Electronics: Connectors, enclosures, and micro mechanical parts.

- Aerospace: Lightweight structural components and complex assemblies.

Is Precision Injection Molding Right for Your Project?

Consider precision injection molding if your project demands:

- High dimensional accuracy and tight tolerances.

- Complex part geometries.

- Consistent quality across production runs.

- Use of high performance thermoplastics.

Partnering with the Right Manufacturer

Selecting an experienced precision injection molding partner is crucial. EI Sales can connect you with reputable manufacturers specializing in precision molding, ensuring your project benefits from expert guidance and quality production.

Ready to explore precision injection molding for your next project? Contact EI Sales today to discuss your requirements and find the ideal manufacturing solution.