When it comes to manufacturing complex metal components, selecting the appropriate production method is critical. Two widely used techniques, Metal Injection Molding (MIM) and Die Casting, each offer unique advantages depending on the application. Whether you are designing a high performance aerospace bracket or a compact medical device housing, understanding the pros and cons of each process can help you make a smarter decision.

What is Metal Injection Molding?

Metal Injection Molding combines the design flexibility of plastic injection molding with the material strength of powdered metallurgy. Fine metal powders are blended with a binder to form a feedstock, which is then injected into a mold. Once molded, the part goes through a debinding and sintering process to remove the binder and fuse the metal particles.

Benefits of MIM:

- Excellent for producing small, complex geometries with tight tolerances

- Capable of using a wide range of high performance metals, including stainless steel and titanium

- Produces high density parts with excellent mechanical properties

- Ideal for parts that require minimal post processing

Considerations:

- Higher upfront tooling costs make it most economical for high volume production

- Limited to small and medium sized parts due to processing constraints

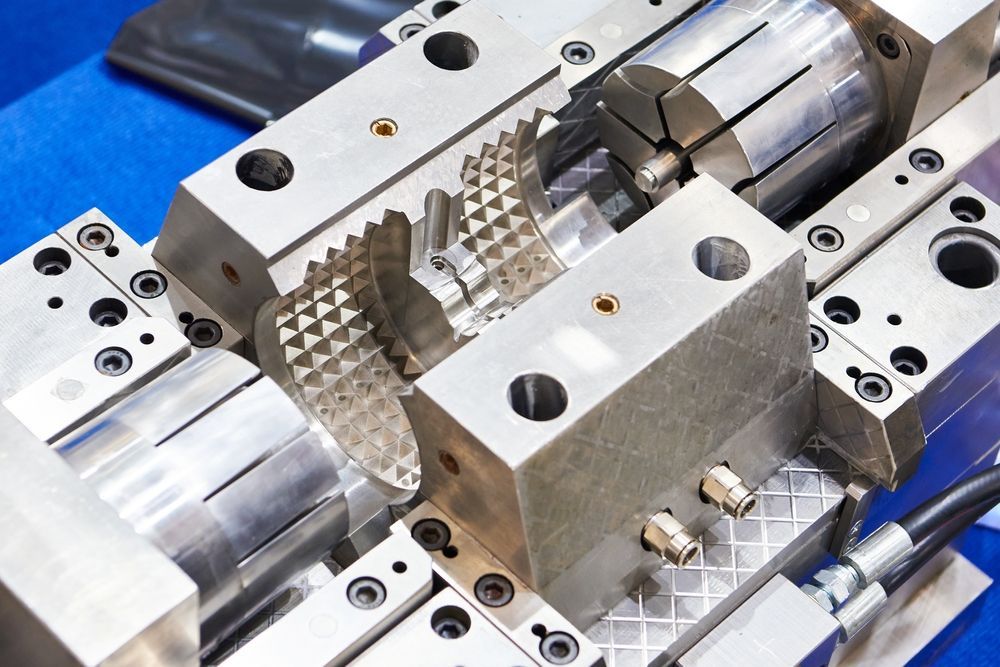

What is Die Casting?

Die Casting involves injecting molten metal into a hardened steel mold at high pressure. The metal solidifies quickly, allowing for rapid cycle times and consistent part replication. This process is commonly used for high volume production of components made from non ferrous metals such as aluminum, zinc, and magnesium.

Benefits of Die Casting:

- High speed process, suitable for large scale manufacturing

- Produces parts with good surface finish and dimensional accuracy

- Often eliminates or reduces the need for machining or finishing

- Lower per part cost for large volumes

Considerations:

- Limited to non ferrous alloys

- Not ideal for extremely intricate or ultra thin parts

- May result in porosity, affecting mechanical strength in critical load bearing applications

MIM vs Die Casting: A Comparison

| Feature | Meta Injection Molding | Die Casting |

|---|---|---|

| Best For | Small, complex, high performance parts | Medium to large parts with consistent shapes |

| Materials | Stainless steel, titanium, tool steels | Aluminum, zinc, magnesium |

| Volume Suitability | Volume Suitability | High volume, faster cycle times |

| Surface Finish | Very good, smooth as molded finish | Very good, smooth as molded finish |

| Very good, smooth as molded finish | Very good, smooth as molded finish | Moderate |

| Precision | Excellent | Good |

| Mechanical Properties | Comparable to wrought metals | Depends on alloy, may include porosity |

| Post Processing | Minimal | Often required |

Use Cases Across Industries

Metal Injection Molding:

- Surgical tools and implantable medical components

- Aerospace locking mechanisms, brackets, and actuation systems

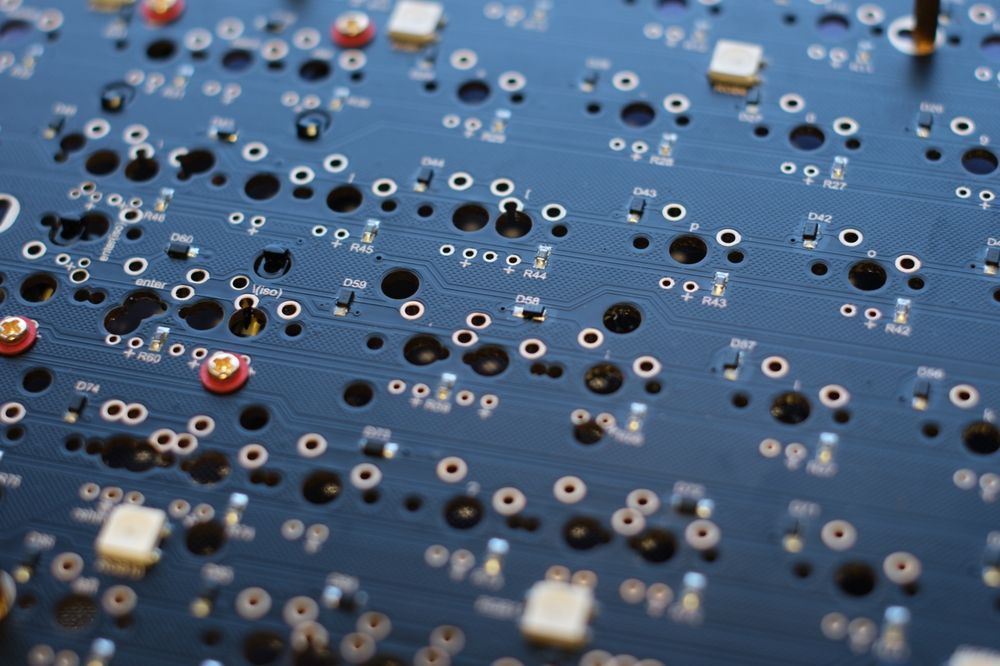

- Miniature gear assemblies and micro connectors in electronics

Die Casting:

- Automotive housings, engine components, and chassis parts

- Consumer electronics casings, device enclosures, and display bezels

- Industrial pump bodies, machinery enclosures, and structural elements

Need Help Finding the Right Manufacturing Partner?

Choosing between Metal Injection Molding and Die Casting depends on your design complexity, part size, material choice, and volume expectations. If you're unsure which method fits your project best, EI Sales can help.

We work closely with vetted U.S. based manufacturers, including experts in both MIM and Die Casting. If your project requires precision metal parts, we can connect you with the right team to bring your concept to life, quickly, reliably, and with confidence.