Blind and Buried Via PCBs

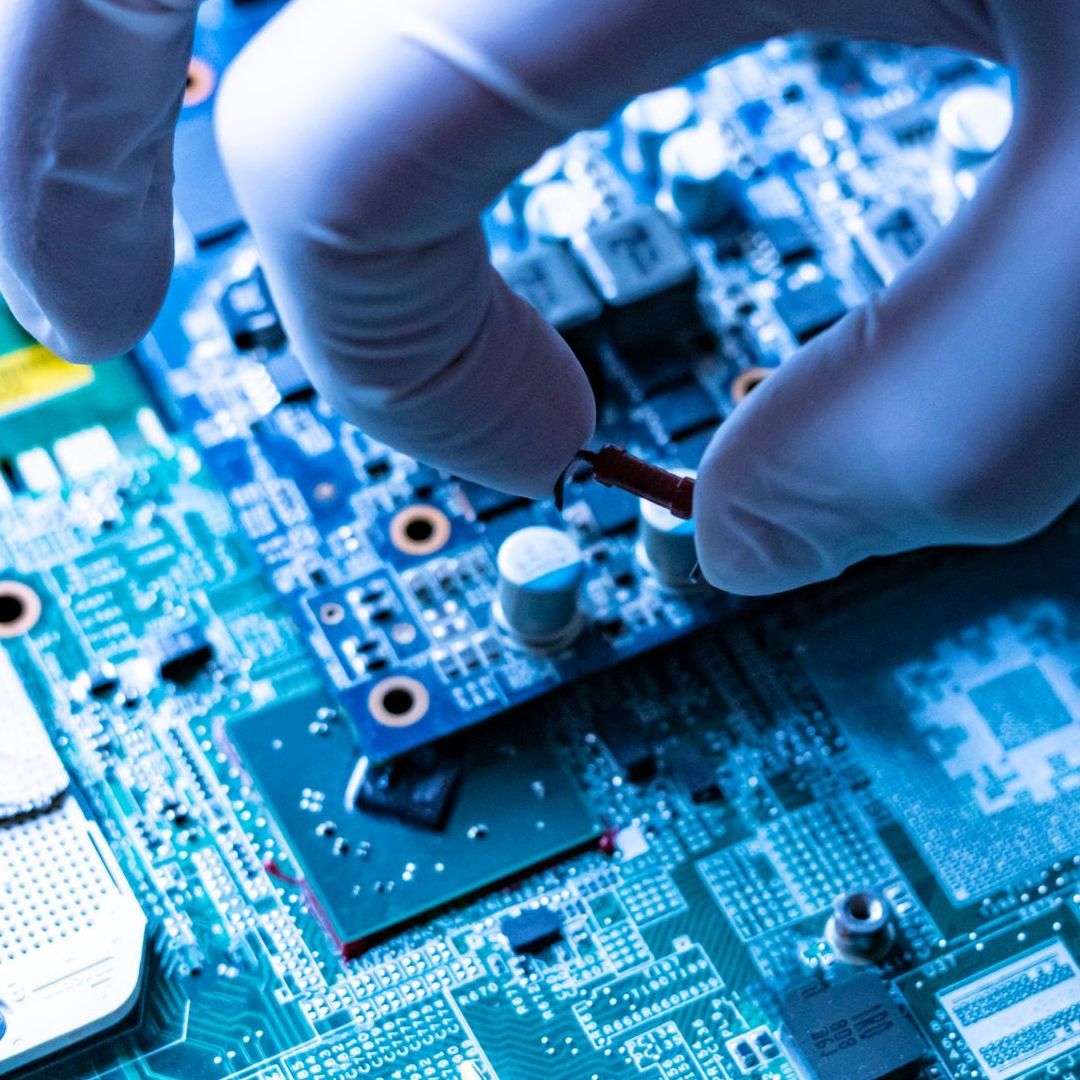

When performance requirements increase and form factors shrink, blind via PCB and buried via technology enable tighter, more efficient designs. These advanced interconnect methods are critical for OEMs working in medical, aerospace, and industrial control systems, where space is limited, and system reliability is a given. EI Sales connects engineers to trusted blind and buried via PCB fabrication partners through a platform built for technical collaboration, compliance confidence, and fast response.

Miniaturization Without Compromise

System density continues to increase, but the available board space rarely does. Blind and buried vias make more complex layouts possible by routing signals between inner layers without consuming surface area. This allows engineers to maintain signal clarity, meet placement constraints, and build in more functionality across applications where both mechanical and electrical margins are tight, including medical and aerospace designs.

Our fabrication partners use a combination of precision drilling and sequential lamination to support high-layer-count boards. These builds are engineered for IPC Class 3 performance across 4 to 24+ layer stack-ups. Applications include implantable and wearable medical devices, aerospace control units, and ruggedized industrial sensor interfaces, where every trace matters and every connection must hold.

Engineered for Multilayer Reliability

Managing signal integrity in dense multilayer designs requires control at every layer transition. Blind and buried vias isolate connections where needed, eliminate unnecessary stubs, and shorten routing paths, leading to cleaner signals and more predictable performance. OEMs building high-speed digital or mixed-signal systems benefit from this reduction in electrical noise and layer interference.

We assist early in the process to support layer sequencing, impedance alignment, and stack-up structure. Material choices, via strategy, and thermal balancing are reviewed with a focus on manufacturability and long-term reliability. Fabrication partners are selected for their experience in high-density builds and ability to maintain tolerances across sequential lamination cycles.

Support from Concept Through Production

Blind via PCB designs come with layout challenges, material considerations, and specific manufacturing rules. Our team works directly with engineers during early design stages to avoid production delays and reduce iteration cycles. We support turn times as quick as 24 or 48 hours. We help evaluate material options, resolve via-in-pad challenges, and align each decision with the build’s technical and compliance goals.

Many projects require IPC Class 3 reliability, traceability, and long-term durability. We work closely with medical, aerospace, and industrial OEMs to meet those benchmarks and assist in navigating review criteria, inspection access, and solderability across tight tolerances. This level of support stays consistent through prototyping, validation, and full production release.

U.S.-Based Fabrication, ITAR Compliant

EI Sales connects OEMs to U.S.-based fabrication teams with proven experience in blind and buried via board builds. These suppliers are ITAR registered, ISO certified, MIL-PRF-31032 certified, and structured to support complex builds that require secure documentation, tight oversight, and controlled turnaround.

For programs where timing and traceability are equally important, domestic production eliminates the uncertainty of offshore delays. We work in real time to keep projects moving, help address engineering changes, and respond to test feedback without disrupting build schedules.

Start Your Project Today!

Bring your next blind or buried via project to a U.S.-based team that understands what's at stake.

Request a stack-up review or ask an advisor how we can help.

Manufacturers Template Contact Us

We will get back to you as soon as possible.

Please try again later.